Rotomolding has a lot of benefits for items. Rotomolding produces pieces that are stronger than those made by other plastic methods since it is a stress-free process. The material most frequently used for rotomolding is polyethylene. One of the strongest materials on the world, polyethylene has a very long lifespan and is resistant to the environment. Parts made of rotomolded polyethylene are frequently lighter than those made of several other materials.

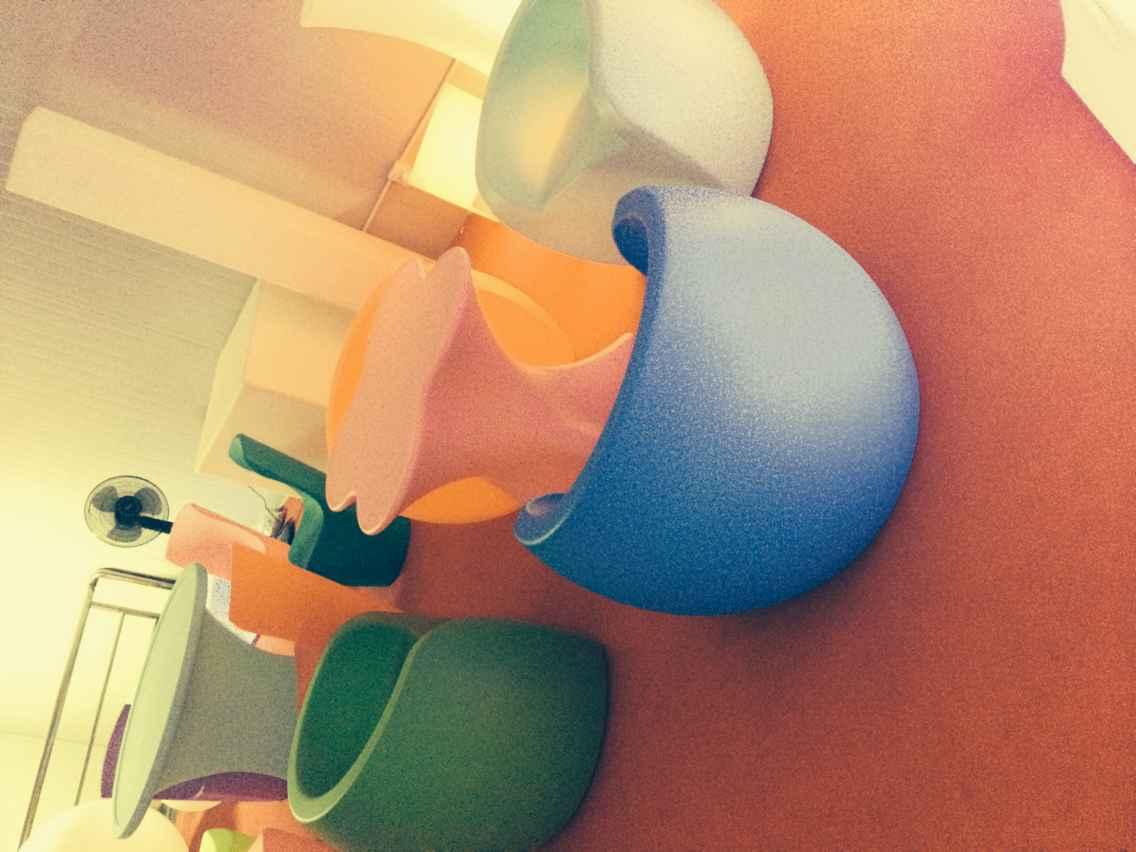

When the right materials are utilized for rotomolding, goods can be used outside and exposed to sunshine with little to no damage. This characteristic leads to the frequent use of rotomolded playground equipment. Numerous chemical tanks are rotomolded because polyethylene can be exposed to several caustic chemicals without degrading.The interior of many stainless steel tanks has been rotomolded with a PE liner.

By using specified grades of certified prime virgin materials, the rotomolding technique can meet FDA regulations for food grade manufacture. The food sector frequently uses a wide variety of rotomolded items due to the wide variety of materials and goods available.

The industrial potential for items made using rotational molding is practically infinite. The transformation of products composed of less resilient materials into rotomolded products is an increasing trend in manufacturing.

Because of the method and the properties of the materials, rotomolding offers a wide range of advantages. Some examples of rotomolding product conversions include pallets, agricultural tanks, drainage piping, laundry carts, department of defense objects, air cargo containers, burial urns and cemetery products, and even tornado shelters.

Rotational molding and polyethylene can both be utilized to increase the lifespan of parts produced of other materials. Another emerging trend is to line metal tanks or components with polyethylene to increase the metal’s lifespan. Tanks made of carbon steel and stainless steel can function efficiently in service for a longer period of time thanks to this extension of their lifespan. Because some of the chemical contents of these tanks are so corrosive or caustic, they will attack or damage the steel materials or even the weld seams, therefore the polyethylene protects the metal tanks in many ways.

While many of these tanks’ metal constructions are vulnerable to these attacks, polyethylene is resilient and ideal for the storage of a range of basic and acidic substances. Through the rotomolding procedure, a specific polyethylene liner can be added to the interior of a tank or component, enhancing an otherwise constrained material’s durability and chemical resistance.

Rotational molding is a method that may be used for both big and tiny pieces and spans numerous industries. This method works for businesses of all sizes because it can produce parts in both large and small volumes. Due to the method’ many advantages in producing high-quality molded products, rotomolding has an increasing potential for businesses and engineers.

Post time: Dec-27-2022